Solid Biofuel From Waste Generated By Agroindustrial Processes In The El Empalme Sector

Biocombustible Sólido A Partir De Residuos Que Generan Los Procesos Agroindustriales Del Sector El Empalme

Show authors biography

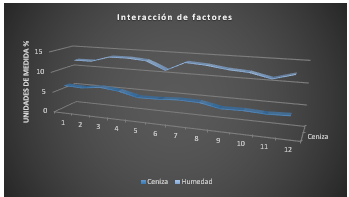

Solid biofuel is obtained by compacting or densifying waste, it does not contain binders, additives or other substances that can deteriorate boilers and heating installations, its content is 100% waste from agro-industrial processes, lignin acts as a natural binder. The main objective is the preparation and physical and chemical characterization of the briquette to be used as a solid biofuel, to Agroindustrial residues such as: rice husk, dust, stone and sawdust. With a completely randomized block design and an ABC factorial arrangement that consisted of 12 treatments and 2 replicates, which corresponds to 24 treatments. The study factors: Factor A (type of mixture), Factor B (shape of the briquettes) and Factor C (size of the briquettes). For the compaction process, molds were designed and manufactured with cylindrical and rectangular shapes of 10 and 15 cm in height. The best treatment was determined by physical and chemical analysis prepared with 4% rice husk, 14% dust, 10% husk, 12% sawdust, square in shape with a size of 10 cm, with the following characteristics: 4.35% ash, 11% humidity, calorific value 5268.20 Kcal / kg, density 1 g / cm3 and a compaction force of 6.51 PSI; This being the outstanding treatment with the desired characteristics in a briquette, we proceeded to carry out temperature and combustion time tests, where it reached a range of (127-240) °C in a time of 30 minutes to be fully calcined.

Article visits 743 | PDF visits