Improvement of pallet manufacturing production-line through work study in the Tropical Pallets company

Mejoramiento de la línea de producción en la fabricación de pallets mediante el estudio de trabajo en Tropical Pallets S.A.

Show authors biography

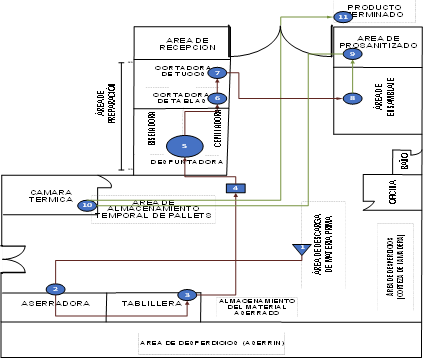

This research project was carried out at the Tropical Pallets company, with the aim of improving the production line in the manufacture of pallets through the work study; For this, a study of all the elements that intervene in the production area was carried out, such as: machines and equipment, operators and jobs, which in relation to all these elements can cause delays in production and possible work accidents. Carrying out a work study makes it possible to determine how the work is carried out in each process, it also helps to determine standard times, to obtain favorable results in contrast to the normal time, eliminating lost times and possible bottlenecks. Through direct observation of the production area, it was possible to verify: the existence of a poor distribution of equipment and machinery at unnecessary distances that affects the time dedicated to production; poor placement of waste and finished products that hinders easy mobility between the different stages of production. For the development of this problem, study tools such as; flow charts, path diagram, analytical diagram and charts that allow to determine the current situation of the company. This study and the redistribution of the plant allowed to considerably reduce the processing time of the pallets, from 21 minutes to 13.5 minutes per unit, that is to say, a saving of 36% of time, with the consequent reduction in costs and increase in the Profits.

Article visits 567 | PDF visits